Across the building materials industry innovation has become a premier focus for product manufacturers. As builders and architects continue to push the boundaries of design, materials continue to adapt to meet those needs. In the natural stone industry, technological innovations have allowed for custom-fabricated material to be created, even to the specifications of individual projects. When considering a custom piece of natural stone, there are a few finishing options to choose from.

Thermal Finish on 2" Sawn Flagstone Piece

Thermal Finish

Thermaling, also known as stone flaming is a process where a high-temperature flame is applied evenly across the smooth (recently sawn) piece of stone, causing it to expand and bring out the texture(video above). This "thermaled" texture is the most common finish for the top surface of a sawn piece, including steps, flagstone, treads, hearths, and wall caps. The texture created from the torch is anti-slip making it the right choice for any surface that is going to be stepped on. This includes applications like landscape steps, pool coping, flagstone walkways, and more. While the top surface of each piece is the popular use for the thermal finish, any sawn side can be torched.

Live Edge

.png?width=550&height=550&name=Liberty%20Hill%20Steps%20(10).png)

Sawn Liberty Hill Steps with Live Edge Rise

Unlike the other two finishes, a live edge is not created by the manufacturing team. "Live edge" is a term that means to leave the sides of the piece natural. For example, the steps above have a live edge across the front(rise) and sides. The sides and rise of these steps are left as they were when the slab arrived at the facility from the quarry and are not altered by the production team. A live edge can be useful for landscape steps, a rustic look for a wall cap, or a custom fireplace hearth. Many of the projects incorporating a live edge are usually sawn on other sides, combining both the ease of installation of a dimensional, sawn piece with the natural look and feel of the live edge. One of the drawbacks of specifying a live edge is that natural sides are not sawn to specific dimensions and fall within a range of sizes.

Rock Face

Rock facing a Dusty Rose Sill

Rock facing is a finishing option popular among steps, hearths, treads, sills and wall caps, typically adding a finished texture to the sides or rise of a sawn piece. Rock facing is the process of using a hammer or chisel to expose the inside of the stone and create a natural-looking texture. This finishing option is meant to give the appeal of a live edge while still being able to fabricate the piece to specific dimensions. In the video above the rise of a sill or water table is being rock faced by a member of the production team.

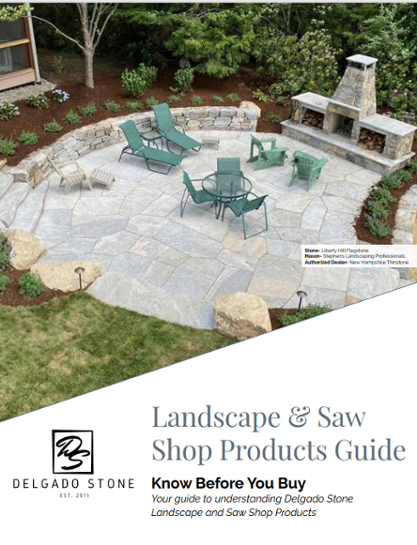

These finishing options allow for almost complete customization of a fabricated piece of natural stone. With the advancements in technology combined with the handwork of the manufacturing team, natural stone has adapted to meet the needs of any project. To learn more about fabricated material options, download the landscape and saw shop spec guide.

-2.png?width=150&height=150&name=Untitled%20design%20(2)-2.png)

COMMENTS